The strange long history of Teflon: the non-subversible product that nothing sticks to

Teflon is a name synonymous with nonstick cookware, but its importance extends far beyond the kitchen. Discovered by chance and developed into one of the most diverse materials of the twentieth century, Teflon's story is a story of innovation, mystery and controversy. This article delves into Teflon's discovery, unique properties, industrial development, applications, and associated risks, and provides a comprehensive overview of this seemingly vandalizing resistant material.

1. Accidental detection of Teflon.

In 1938, a young chemist named Roy Plunkett, working for DuPont, was experimenting with refrigerants when he found something unexpected. Plunkett was trying to access a new type of refrigerant by polymerizing tetrafluoroethylene (trafluoroethylene TFE) when he was surprised that this gas turned into a white wax inside his storage container. This material, which resisted corrosion and showed an unusually low coefficient of friction, would later be called Polytetrafluoroethylene (Polytetrafluoroethylene PTFE) and registered as a trademark as Teflon.

Recommend

2. Teflon chemistry and its effect on properties.

Teflon's remarkable properties are deeply rooted in its unique chemical structure. Polytetrafluoroethylene (PTFE), the polymer that makes up Teflon, has the chemical formula (C₂F₄)n. This formula represents the repeating units (C₂F₄) of the n carbon–fluorine atoms that make up the polymer chain. Each unit is made up of two carbon atoms, each bonded to two fluorine atoms.

The carbon-fluorine bond is one of the strongest bonds in organic chemistry, giving Teflon its outstanding durability and resistance to chemical reactions. The dense fluorine atoms form a shield around the backbone of the carbon chain, protecting it from interaction with other substances, which explains Teflon's unusual chemical inertness.

The linear structure of PTFE molecules leads to weak intermolecular forces, contributing to a decrease in the coefficient of friction. This means that when other materials come into contact with Teflon, they experience little resistance, which is why it has effective non-stick properties. In addition, the strong bonds between carbon and fluorine give Teflon its high melting point and thermal stability, making it suitable for use in high-temperature environments.

Teflon's hydrophobic nature, which means that it expels water, is another consequence of its chemical structure. Water and other polar materials are unable to form hydrogen bonds with Teflon, causing them to curl and roll over its surface. This property, combined with its non-reactivity and slippage, makes Teflon an ideal material for coatings in various applications, from cookware to protective fabrics.

3. Unique properties of Teflon.

Teflon's unique properties stem from its molecular structure. PTFE is made up of carbon atoms completely surrounded by fluorine atoms, creating strong bonds that make the material virtually inamenable to chemical reactions. This results in many unusual properties, including a high melting point (about 327°C or 620°F), resistance to almost all chemicals, and one of the lowest coefficients of friction of any solid. These properties make Teflon an invaluable material in various industrial and consumer applications.

4. Special characteristics: the phenomenon of non-adhesion.

Perhaps the most famous property of Teflon is its non-stick quality. The molecular structure of Teflon creates such a slippery surface that almost nothing sticks to it. This property is what makes Teflon-coated cookware so popular, allowing easy cooking and cleaning. Outside the kitchen, Teflon's non-stick quality is used in many industries, from textiles to electronics, where it prevents materials from sticking to machinery or other surfaces.

5. Industrial development and marketing of Teflon.

After its discovery, the development of Teflon for commercial use was slow but steady. During World War II, its corrosion resistance made it an ideal material for lining equipment used in the Manhattan Project, where there was highly corrosive uranium hexafluoride. In the postwar years, DuPont began exploring Teflon's potential in consumer products, which eventually led to its introduction to the cookware market in the fifties. The ease of cooking and cleaning food on Teflon-coated pans has revolutionized kitchen utensils.

6. Global production and economic impact of Teflon.

Teflon production has become an important global industry. The United States, China and Europe are the main producers of Teflon, with the global market valued at billions of dollars annually. Teflon is used in a myriad of products, from aerospace and electronics to clothing and medical devices. Its extensive applications have cemented its position as one of the most versatile materials ever developed.

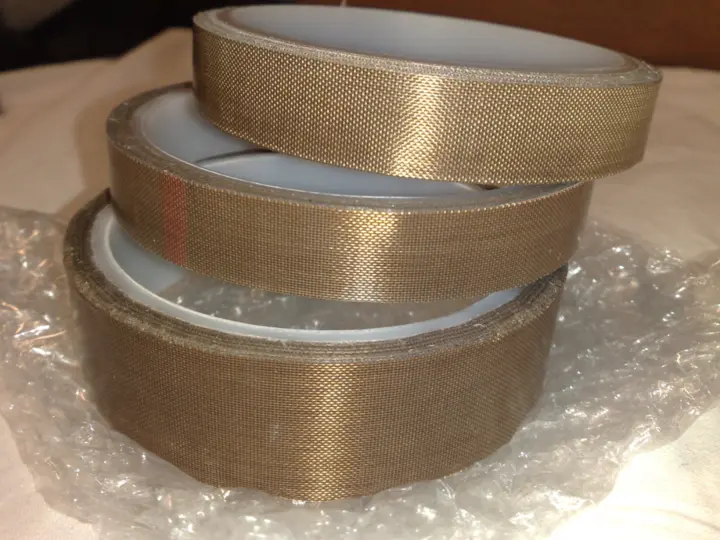

7. Teflon applications and uses.

Teflon applications are incredibly diverse. In the aerospace industry, it is used to coat wires and cables to prevent friction and withstand high temperatures. In the medical field, Teflon, due to its biological compatibility and non-reactive nature, is used to manufacture artificial body systems. In electronics, Teflon is used as an insulator in cables and connectors. In addition, Teflon is used in the textile industry to manufacture waterproof and stain resistant fabrics. Its non-stick property also made it indispensable in the production of cookware and bakeware.

8. Risks and dangers associated with Teflon.

Despite its many advantages, Teflon is no exception to the controversy. Teflon production involves the use of a chemical called perfluorooctanoic acid (perfluorooctanoic PFOA), which has been linked to environmental pollution and health concerns. PFOA has been found to persist in the environment and accumulate in the human body, leading to concerns about its potential role in causing cancer and other serious health problems. In response to these concerns, manufacturers have stopped using PFOA in Teflon production, but questions about the safety of alternative chemicals remain.

9. The Future of Teflon: Innovation and Sustainability.

As the world moves towards more sustainable practices, the future of Teflon is uncertain. Efforts are underway to develop safer and more environmentally friendly alternatives to traditional PTFE. In addition, the research focuses on improving recycling methods and disposing of Teflon products, reducing their environmental impact. While Teflon's unique properties ensure its continued use for the foreseeable future, sustainability and safety challenges will continue to shape its evolution.

Teflon's journey from a lab accident to a ubiquitous substance in our daily lives is a testament to human ingenuity and the power of chemistry. Its unique properties have made it indispensable in various industries, but its environmental and health risks have also raised important questions. As we look to the future, balancing the benefits of Teflon with the need for sustainability will be key to ensuring that this wonderful material continues to serve humanity without compromising the health of the planet.

![]()

Success Guide - How to discover your passion?

Discovering your passion is a personal journey that brings meaning and joy to life. It’s about finding what excites you, motivates you, and makes you feel alive. With patience, reflection, and trying new experiences, you can uncover what truly inspires you without needing to spend a fortune. more- ADVERTISEMENT

![]()

Beyond Burj Khalifa: Uncovering the Spirit of Dubai through its Metro

Dubai Metro isn't just a ride—it's a futuristic journey wrapped in art, culture, and record-breaking feats. From Wi-Fi on board to stations named after shops, it’s where innovation meets daily buzz. Just don’t fall asleep, or it might cost you AED 300! more- ADVERTISEMENT

![]()

How to overcome your fear of flying

How to overcome your fear of flying more- ADVERTISEMENT

![]()

A book you may be interested in: Dopamine fasting

A book that might interest you - Dopamine Fast more- ADVERTISEMENT

![]()

Sacred places in the Andes: 7 secrets of Machu Picchu

Machu Picchu isn't truly the lost city of the Incas, and it's not as forgotten as once believed—locals were living there when rediscovered. Many marvels are hidden underground, and if you're up for a sweaty climb, you can skip the pricey bus and enjoy epic views for free. more- ADVERTISEMENT

![]()

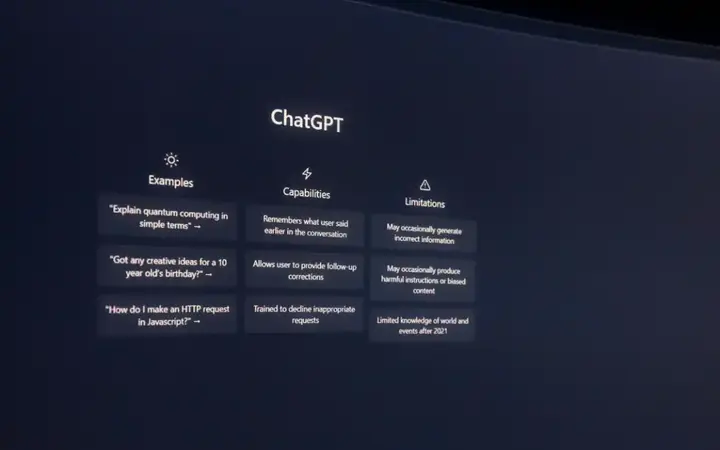

The best ChatGPT alternatives, including what is free

ChatGPT is an advanced language AI revolutionizing communication and creativity with human-like conversations and text generation. Alongside it, impressive free alternatives like Google's Bard, Jasper Chat, Bing AI, and Perplexity AI offer unique features—from creative writing to fact-based search—making AI tools more accessible, powerful, and tailored to user needs. more- ADVERTISEMENT

![]()

Habits that make you smarter

Becoming smarter isn’t about talent—it's about building habits that boost your brain. Exercise, mindfulness, learning new skills, and reading can sharpen your mind. Add good sleep, social interaction, and goal setting, and you're on your way to a smarter, healthier you. Intelligence grows with consistent practice. more- ADVERTISEMENT

![]()

My strategies for developing business confidence

Asking for a raise taught me a powerful lesson: confidence and self-advocacy matter. Despite battling impostor syndrome and anxiety, I learned to challenge my inner critic, celebrate my wins, and take risks. That one bold step led to growth, success, and a stronger belief in myself ever since. more- ADVERTISEMENT

![]()

How to learn German for free in 6 months

Learning German opens doors to job and study opportunities in Germany, Austria, and Switzerland. With dedication—three hours a day—you can reach intermediate level in six months. YouTube channels like Deutsch mit Mira, German with Mr. Shehata, and Khaled Bozan make learning fun and accessible for everyone. more- ADVERTISEMENT

![]()

Which determines whether it smells good or bad?

Your nose can detect thousands of scents thanks to millions of odor receptors, shaping your experiences and memories. Smells trigger emotional responses, connect to past events, and even signal danger—like the foul scent of rotten eggs. From birth, our genes and experiences guide how we react to different odors. more- ADVERTISEMENT